IK-200 pre laid polymer self-adhesive membrane waterproof coiled material [non asphalt] and IK-550 polyvinyl chloride (PVC) waterproof coiled material. The former is used for underground pre paving, which is integrated with concrete, such as seamless connection of human skin and meat, which makes the underground waterproof effect excellent and easy to maintain. It is widely used in basement, subway, tunnel and pipe bottom.

Application

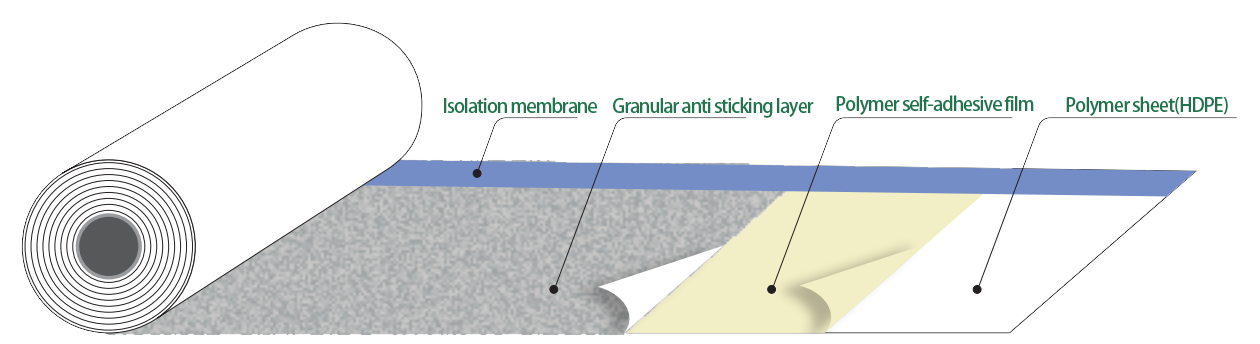

Specifications

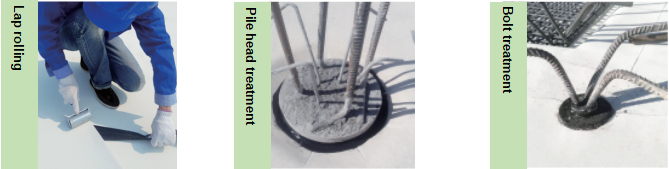

Detail processing

Technical parameter

|

No. |

Item |

Index |

|||

|

P |

PY |

R |

|||

|

1 |

Soluble content/(g/m2) |

|

2900 |

|

|

|

2 |

tensile property |

Pulling force/(N/50 mm) ≥ |

600 |

800 |

350 |

|

Tensile strength/MPa ≥ |

16 |

- |

9 |

||

|

Elongation at break of membrane/%≥ |

400 |

- |

300 |

||

|

Elongation at maximum tension/%≥ |

- |

40 |

- |

||

|

Phenomenon during stretching |

No separation between the adhesive layer and the subject material or tire base |

||||

|

3 |

Tear strength of nail rod/N ≥ |

400 |

200 |

130 |

|

|

4 |

Elastic recovery rate/% ≥ |

- |

- |

80 |

|

|

5 |

Puncture resistance/N ≥ |

350 |

550 |

100 |

|

|

6 |

Impact resistance(0.5kg*m) |

no-leakage |

|||

|

7 |

Anti static load |

20kg,no-leakage |

|||

|

8 |

Heat resistance(70℃,2h) |

80℃,2hNo slip, flow and drip |

70℃,2hNo slip, flow and drip |

100℃,2hNo slip, flow and drip |

|

|

9 |

Low temperature bending |

Main material - 35 ℃, no crack |

- |

Main material and adhesive layer - 35 ℃, no crack |

|

|

10 |

Low temperature flexibility(-20℃) |

Adhesive layer - 25 ℃, no crack |

-20℃,no crack |

- |

|

|

11 |

Oil permeability/Pcs ≤ |

1 |

2 |

1 |

|

|

12 |

Water channeling resistance(Hydraulic gradient) |

0.8MPa/35mm,4hNo water channeling |

|||

|

13 |

Impermeability(0.3Mpa 120min) |

Impervious |

|||

|

14 |

Peeling strength of coil anti sticking treatment/(N/mm) ≥ |

0.1Or non bonding |

|||

|

15 |

Thermal aging(80℃,168h) |

Tensile holding force/% ≥ |

90 |

80 |

|

|

Elongation retention/% ≥ |

80 |

70 |

|||

|

Low temperature bending |

Main material - 32 ℃, no crack |

- |

Main material and adhesive layer - 32 ℃, no crack |

||

|

Low temperature flexibility |

Adhesive layer-23℃,no crack |

-18℃,no crack |

- |

||

|

16 |

Dimensional change rate/% ≤ |

±1.5 |

±0.7 |

±1.5 |

|