Application

Specifications

Types

|

No. |

Item |

Index |

|||||

|

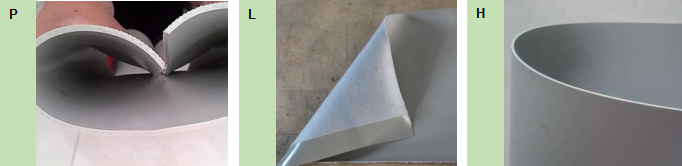

P(Enhanced) |

L(Backing type) |

H(Homogeneous type) |

|||||

|

1 |

Thickness of resin layer on middle tire base,mm ≥ |

0.40 |

- |

||||

|

2 |

Maximum tension,N/cm ≥ |

250 |

200 |

- |

|||

|

Tensile strength,MPa ≥ |

- |

- |

12 |

||||

|

3 |

Elongation at maximum tension,% ≥ |

15 |

- |

- |

|||

|

Elongation at break,% ≥ |

- |

250 |

500 |

||||

|

4 |

Dimensional change rate of heat treatment,% ≤ |

0.5 |

1.0 |

2.0 |

|||

|

5 |

Low temperature bending |

-40℃ No crack |

|||||

|

6 |

Impermeability |

0.3MPa,2h,Impervious |

|||||

|

7 |

Impact resistance |

0.5kg·m,Impervious |

|||||

|

8 |

Anti static load |

20kgImpervious |

- |

- |

|||

|

9 |

Joint peel strength,N/mm ≥ |

3.0 |

4.0 |

||||

|

10 |

Right angle tear strength,N/mm ≥ |

- |

- |

60 |

|||

|

11 |

Trapezoid tear strength,N ≥ |

450 |

250 |

- |

|||

|

12 |

Water absorption(70℃ 168h),% ≤ |

4.0 |

|||||

|

13 |

Thermal aging (115℃) |

Time |

672h |

||||

|

Appearance |

No blistering, cracks, delamination, bonding and holes |

||||||

|

Maximum tension retention,% ≥ |

90 |

90 |

- |

||||

|

Tensile strength retention,% ≥ |

- |

- |

90 |

||||

|

Elongation retention at maximum tension,% ≥ |

90 |

- |

- |

||||

|

Elongation at break retention,% ≥ |

- |

90 |

90 |

||||

|

Low temperature bending |

-40℃ No crack |

||||||

|

14 |

Chemical resistance |

Appearance |

No blistering, cracks, delamination, bonding and holes |

||||

|

Maximum tension retention,% ≥ |

90 |

90 |

- |

||||

|

Tensile strength retention,% ≥ |

- |

- |

90 |

||||

|

Elongation retention at maximum tension,% ≥ |

90 |

- |

- |

||||

|

Elongation at break retention,% ≥ |

- |

<span style="font-fam | |||||