KINGWOOL®Ceramic fiber board are furnace refractory and insulation material, take ceramic fiber as the main raw materials, after fiber processing, slag removing, then add some binder, through vacuum forming process and drying process, to be made into high strength fiber board.

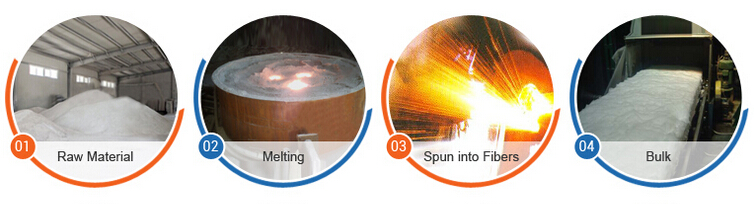

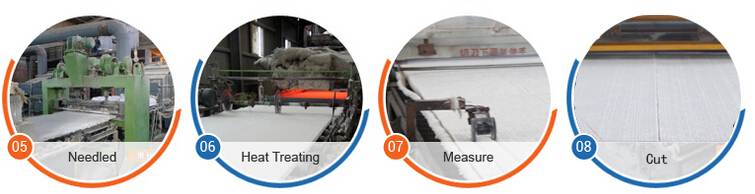

KINGWOOL® ceramic fiber blanket is made of high quality alumina-silicate ceramic fiber by using double side needling methods which improve the tensile strength and the flatness of the ceramic fiber blanket. Our ceramic fiber blanket contains no organic binders which guarantee the stability and constructability of the ceramic fiber blanket at both high temperature and low temperature. What’s more, We are one of the manufacturer who can produce ceramic fiber blanket of 6mm thickness.

Standard Dimensions:

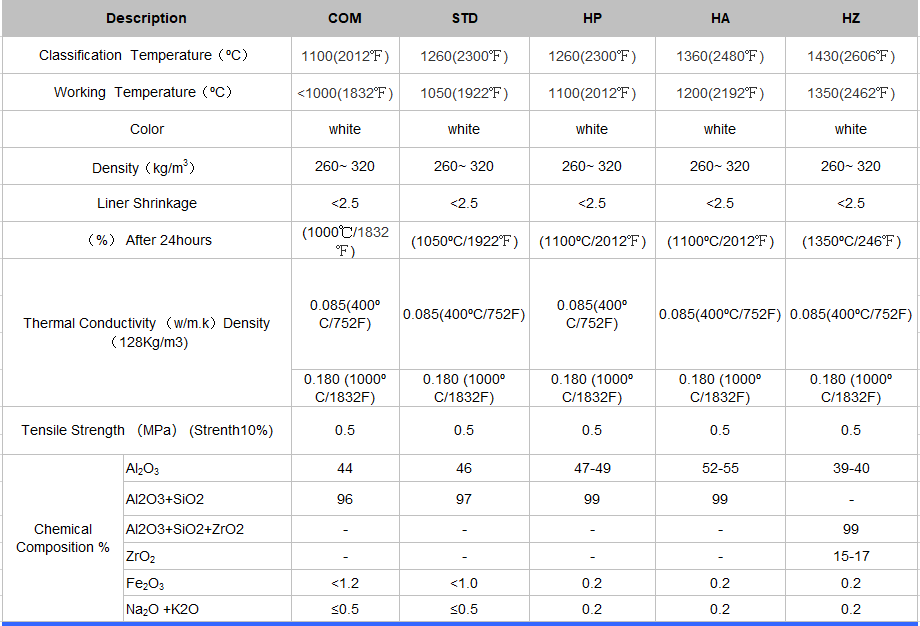

Density: 260~ 320kg/m3

Dimention: 900x600mm / 600x400mm

Thickness:10mm-80mm

KINGWOOL® Ceramic Fiber Board is composed of long, flexible, interwoven FIBERs manufactured by the 'blown' and 'spun'

process yielding a strong, lightweight yet durable fiber board for applications in a temperature range from 1260℃ to 1600℃.

Application of KINGWOOL® Ceramic Fiber Board:

1. Refractory lining for industrial furnaces in walls , roofs, doors, stacks etc

2. Combustion chamber liners, boilers and heaters

3. Back-up insulation for brick and monolithic refractories

4. Transfer of molten aluminium and other non-ferrous metals

5. Expansion board joints

6. Barrier against flame or heat

7. Hot face layer for high velocity or abrasive furnace atmosphere

Take a look at our range of insulation and call our team of experts today for any queries or advice on 8615690166576.