Exterior wall thermal insulation material specifically refers to a kind of thermal insulation material used for building walls. According to their internal composition, they can be divided into inorganic thermal insulation materials and organic thermal insulation materials. The common ones are glass wool board, rock wool board and vacuum insulation board. The external wall insulation material is an important factor affecting building energy conservation. Now they have become an indispensable part of buildings, so how to install them?

At present, the most commonly used external wall insulation method is thin plaster external wall external insulation system. The following describes the system construction methods of the above three common exterior wall thermal insulation materials.

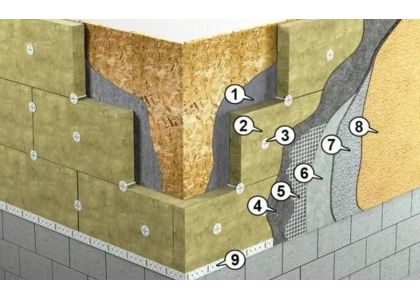

1. Construction technology of thin plastering external insulation system of glass wool board and rock wool board

(1) Basic treatment and acceptance of wall; (2) Hanging vertical line, triangular plate and elastic control line; (3) Mounting bracket; (4) Preparation of plastering mortar; (5) Scrape off the thin layer on the back of the rock wool board. (6) Preparation of adhesive; (7) Rock wool board pasting; (8) Scrape the thin surface mortar in front of the rock wool board for interface treatment; (9) Wipe the first layer of surface mortar; (10) Laying the first layer of glass fiber mesh; (11) Installation of anchors; (12) Apply the second layer of plastering glue; (13) Laying the second layer of glass fiber mesh; (14) Plastering the third layer of plastering mortar; (15) Fix the stressed keel of the curtain wall; (16) Installation of curtain wall block materials; (17) Curtain wall plugging joint treatment.

2. Construction process of vacuum insulation board thin plastering external wall external insulation system

(1) Base course treatment, waterproof mortar leveling; (2) Suspension datum line and elastic control line; (3) Mounting bracket; (4) Preparation of adhesive; (5) Gluing and pre gluing turnover net; Vacuum insulation board; (7) Install anchor bolts; (8) Filling and edge treatment; (9) Preparation of plastering paste; (10) Apply the first layer of plastering paste; (11) Lay ordinary alkali resistant glass fiber mesh; (12) Wipe the second layer of plastering mortar; (13) Waterproof treatment of system details; (14) Insulation system engineering acceptance.

It can be seen that for the same thin plastered external wall external insulation system, the construction process of the three materials is roughly the same, and the insulation board basically adopts the method of bonding and anchoring. It is worth noting that polystyrene board is an organic material, and the highest fire rating can only reach grade B1. When used in buildings with high requirements for fire performance, other measures need to be taken, such as fire isolation belt; Rock wool board has high water absorption and is usually used. The closed curtain wall system requires two layers of fiberglass mesh. Vacuum heat insulation board is a new type of energy-saving green building material. It is an inorganic material with fire resistance and the best heat insulation effect among the three. It is thin, light and easy to construct. The construction process is also the simplest and fastest of the three processes, saving time and labor.